Autoclaved Aerated Concrete (AAC)

Formed as a result of reaction of Aluminum on a proportionate blend of lime, Cement & flyash, the hydrogen gas that escapes creatos millions of tiny air cell's giving it a strong honeycomb like structure.

- Aluminum

- Gypsum

- Lime 20%

- Cement 20%

- Flyash 60%

It is further strengthened by high pressure steam Curing in Autoclaves.

Invented in 1923, AAC now accounts for 40 % of all construction in, UK 60 % of all construction in Germany. The rising in demand in India has been so phenomenal that in last 3 years the production has increased by almost 500 %

- SPECIFICATIONS

| PARAMETER | VALUE |

|---|---|

| Density (Oven Dry) | 550 - 650 kg/m3 |

| Compressive Strength | > 3 Mmm2 (IS 2185) |

| Shear Strength | o.6 |

| Modulus of Elasticity | 2040 Mpa |

| Coefficient of Thermal Expansion | 8.1x10^-6 K^-1 |

| Water Absorption (at equilibrium) | <15% |

| Thermal Conductivity | 0.16 w/m°k |

| Thermal Resistance (R Value) | 0.46 m2-0K/w |

| Drying Shrinkage | 0.04% |

| Fire Rating | 4 Hrs. (for 200 mm wall) |

| Sound Transmission Class Rating | 44 db |

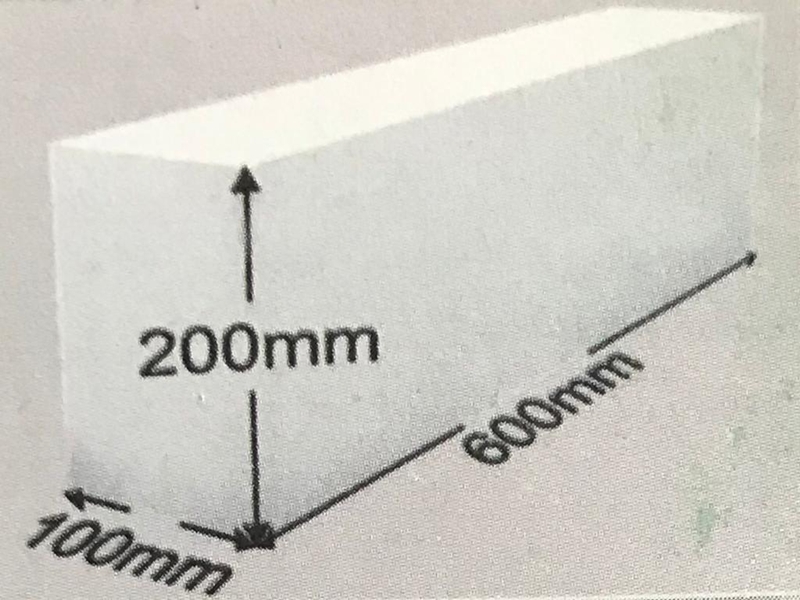

- DIMENSIONS

| PARAMETER | VALUE | |

|---|---|---|

| Length | 600mm | 24" |

| Hight | 200mm | 8" |

| Thickness | 75/100/125/150/200/225mm | 3"/4"/5"6"/8"/9" |

| Tolerance | -0.01 |

CONTACT US

Magiclite Building Solutions

Office:Satara-Koregaon Road, Near Krishna Nagar Bus Stop, Satara 415003.

Factory:Sr.No. 6/1+2,Plot No-6,Near Planet Furniture Old MIDC,Satara 415004.

Factory:Sr.No. 6/1+2,Plot No-6,Near Planet Furniture Old MIDC,Satara 415004.

Leave A Message